Top 5 Factors to Consider When Choosing the Right Forklift Battery

When selecting the right forklift battery, several critical factors come into play that can significantly influence operational efficiency and overall productivity. A report by the Industrial Truck Association highlights that the choice of forklift battery can impact not only the performance of the forklift itself but also the costs associated with energy consumption and maintenance. With the growing shift towards electric forklifts, which are projected to represent over 60% of total forklift sales in the coming years, understanding the nuances of forklift battery technology is essential for businesses aiming to stay competitive in the logistics and warehousing industry.

Moreover, proper battery selection can lead to enhanced safety and reduced downtime. According to a study conducted by the National Institute for Occupational Safety and Health, the risk of accidents in warehouses can be significantly decreased with the right equipment. A suitable forklift battery not only ensures the vehicle operates efficiently but also aligns with sustainable practices as more companies strive for greener solutions. This underscores the importance of evaluating the specifications, capacity, and longer-term costs associated with forklift batteries, making it imperative for decision-makers to invest time in making informed choices.

Understanding Your Forklift’s Power Requirements

When selecting the right forklift battery, understanding your forklift’s power requirements is crucial. Each forklift model comes with a specific power demand based on its capacity, operational tasks, and expected runtime. Factors such as weight, type of cargo, and frequency of use can influence these requirements. By assessing your forklift's specifications, you can determine the voltage and amp-hour rating needed to ensure optimal performance and efficiency.

Additionally, consider the operating environment and the types of tasks the forklift will perform. For example, if you're using the forklift for heavy lifting in a warehouse setting, you'll need a battery that can provide consistent power over extended periods. Conversely, if the forklift is used sporadically for lighter loads, a battery with a lower capacity may suffice.

Thoroughly evaluating these power needs will help you choose a battery that not only meets operational standards but also enhances productivity and extends the life of your equipment.

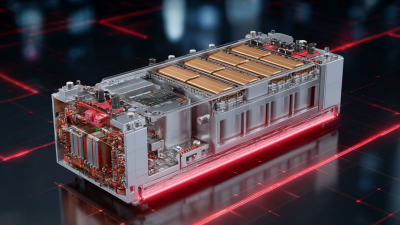

Evaluating Battery Types: Lithium-ion vs. Lead-acid

When evaluating forklift battery options, the two primary types to consider are lithium-ion and lead-acid batteries. Lithium-ion batteries, known for their high efficiency, can provide up to 30% more runtime compared to traditional lead-acid counterparts, making them an increasingly popular choice in the warehousing and manufacturing sectors.

According to a report by the Electric Power Research Institute, lithium-ion batteries can charge faster, taking just about 1 to 2 hours for a full charge, compared to the 8 to 12 hours needed for lead-acid batteries. This improved charging capability allows for more flexible work shifts and reduces downtime.

Tips: Consider the operational demands of your facility when choosing a battery type. If your operation involves multiple shifts or requires fast charging, lithium-ion may be the superior choice. Additionally, factor in the maintenance aspect; lithium-ion batteries typically require less upkeep than lead-acid, which can benefit your bottom line and enhance productivity.

On the other hand, lead-acid batteries present a more cost-effective upfront investment and have a long-standing history in the industry. However, they usually require regular maintenance, such as watering and equalization charges, and their lifespan is often shorter—averaging about 1,500 cycles compared to around 3,000 cycles for lithium-ion. For companies with lower discharge needs and budget constraints, lead-acid batteries can still serve as a reliable option while offering adequate performance.

Assessing Battery Lifespan and Maintenance Needs

When selecting the right forklift battery, assessing battery lifespan and maintenance needs is crucial for ensuring optimal performance and reducing downtime. According to a report from the Industrial Truck Association, the average lifespan of a lead-acid forklift battery is between 1,500 to 2,000 cycles, whereas lithium-ion batteries can last up to 5,000 cycles. This significant difference means that companies must weigh their operational demands against potential battery longevity and the associated costs.

Maintenance is another vital factor in the battery selection process. Lead-acid batteries require regular watering, equalization charges, and proper cleaning to extend their service life, adding to the operational burden. In contrast, lithium-ion batteries are generally maintenance-free, eliminating the need for routine watering and resulting in lower labor costs over time. A study by the Electric Power Research Institute indicates that businesses can save up to 20% on maintenance costs when opting for lithium-ion solutions. By closely examining these aspects, companies can make more informed decisions that align with their productivity goals and budget constraints.

Top 5 Factors to Consider When Choosing the Right Forklift Battery - Assessing Battery Lifespan and Maintenance Needs

| Factor | Description | Lifespan (Years) | Maintenance Needs |

|---|---|---|---|

| Battery Type | Different battery types (Lead Acid, Lithium-ion) have varying performance and lifespan. | 3-7 | Regular maintenance required, especially for Lead Acid. |

| Capacity | Measured in amp-hours (Ah), it indicates how much power the battery can deliver. | 4-8 | Monitor capacity and ensure proper charging cycles. |

| Charge Time | The time it takes to fully charge the battery impacts operational efficiency. | Varies | Follow manufacturer guidelines for optimal charging. |

| Operating Temperature | Batteries perform differently at varying temperatures, affecting lifespan. | 5-10 | Keep batteries within recommended temperature ranges. |

| Cost | Initial investment vs. long-term performance and cost-effectiveness. | Varies | Consider total cost of ownership including maintenance. |

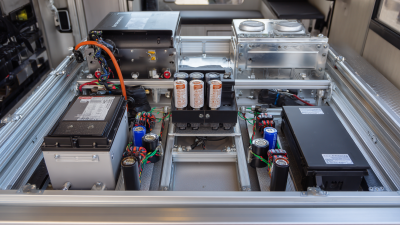

Determining Charging Infrastructure and Compatibility

When selecting the right forklift battery, the charging infrastructure and compatibility play a crucial role in ensuring optimal performance and longevity. First and foremost, it is essential to assess the existing charging facilities in your operation. This includes evaluating the voltage specifications and the type of chargers currently in use. A mismatch between the battery and the charger can lead to inefficient charging, potential damage, or reduced battery life. Additionally, understanding the space and resources available for charging can influence the choice of battery, as some solutions require more extensive setups than others.

Another critical aspect is the compatibility of the battery with the forklift model. Different forklifts may have varied requirements for battery size, weight, and type, such as lead-acid or lithium-ion. Ensuring compatibility not only impacts performance but also affects the overall efficiency of material handling operations. It’s advisable to consult the forklift manufacturer’s specifications and guidelines to find a battery that aligns with both the operational needs and the existing charging infrastructure. By meticulously examining these factors, businesses can make informed decisions that enhance productivity and reduce operational costs in the long run.

Analyzing Cost vs. Performance for Long-term Value

When selecting the right forklift battery, the balance between cost and performance plays a crucial role in ensuring long-term value. High initial costs can be associated with advanced battery technologies, such as lithium-ion, which offer greater energy efficiency and longer lifespan. However, when evaluating their impact on overall operational expenses, these batteries often prove to be more economical over time due to reduced maintenance requirements and higher cycle counts.

Conversely, opting for cheaper lead-acid batteries might seem appealing due to their lower upfront investment. Yet, the trade-off often includes higher maintenance demands and shorter operational lifespans, leading to increased replacement frequency and associated costs. Businesses need to consider the total cost of ownership rather than just the purchase price. By analyzing how each battery type performs against the specific needs of the operation, companies can make informed decisions that support productivity while maximizing their return on investment.

Related Posts

-

How Best Forklift Battery Optimizes Warehouse Efficiency with Real World Applications

-

5 Top Battery Storage Solutions Revolutionizing Energy Management in 2023

-

The Ultimate Guide to Maximizing Efficiency with Energy Storage Batteries: Key Trends and Innovations

-

Unlocking the Power: How Lithium RV Batteries Outperform Lead-Acid with 30% More Efficiency and Lifespan

-

Unlocking the Future: Advantages of the Best Energy Storage LiFePO4 Battery for Global Buyers

-

The Future of Energy Storage Exploring the Benefits of Rechargeable Lithium Batteries in Sustainable Technology