2025 Top 5 Vacuum Circuit Breaker Innovations for Enhanced Safety and Efficiency

As the electrical power industry continues to evolve, the demand for innovative solutions that enhance safety and efficiency has never been more critical. The vacuum circuit breaker (VCB) technology is at the forefront of this evolution, offering remarkable advantages such as low maintenance costs, superior performance in terms of insulation, and rapid operational speed. According to a recent report by the International Energy Agency (IEA), the adoption of advanced circuit breaker technologies is expected to grow by over 15% annually, emphasizing the need for enhanced safety standards in electrical systems.

Industry expert Dr. Sarah L. Thompson, a leading researcher at the Electrical Engineering Research Institute, highlights the importance of focusing on innovation within the vacuum circuit breaker sector. She asserts, "The future of energy efficiency lies in embracing cutting-edge technologies such as vacuum circuit breakers, which not only provide reliability but also significantly reduce carbon footprints." As utilities and industries seek sustainable solutions, innovations within VCB technology promise to deliver exceptional performance that meets the rigorous requirements of modern electrical grids.

With the ongoing push toward renewable energy integration and smarter grid systems, the landscape for vacuum circuit breakers is shifting dramatically. In this article, we will explore the top five innovations in vacuum circuit breaker technology for 2025, focusing on how these advancements are set to redefine safety and efficiency across various applications.

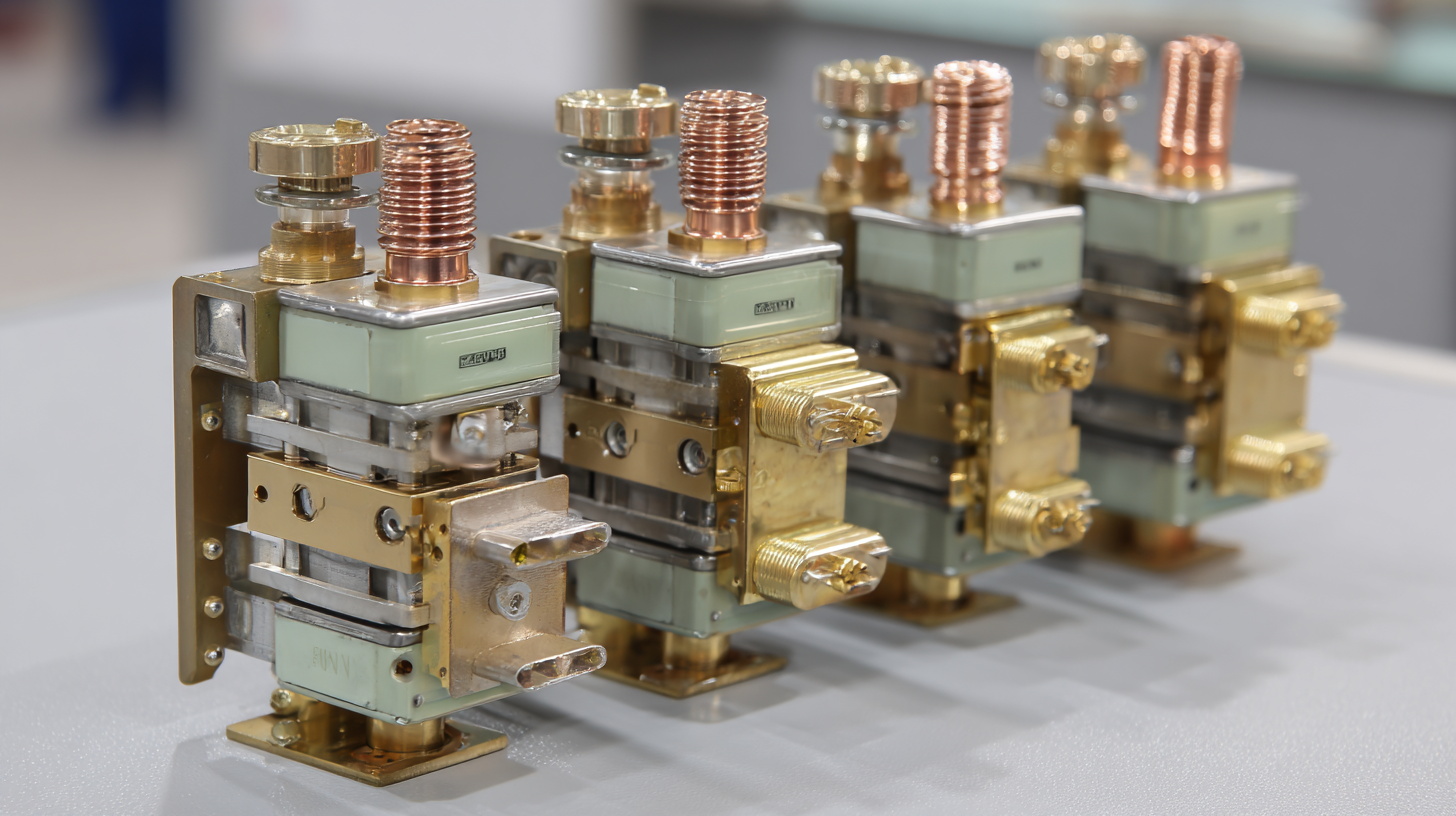

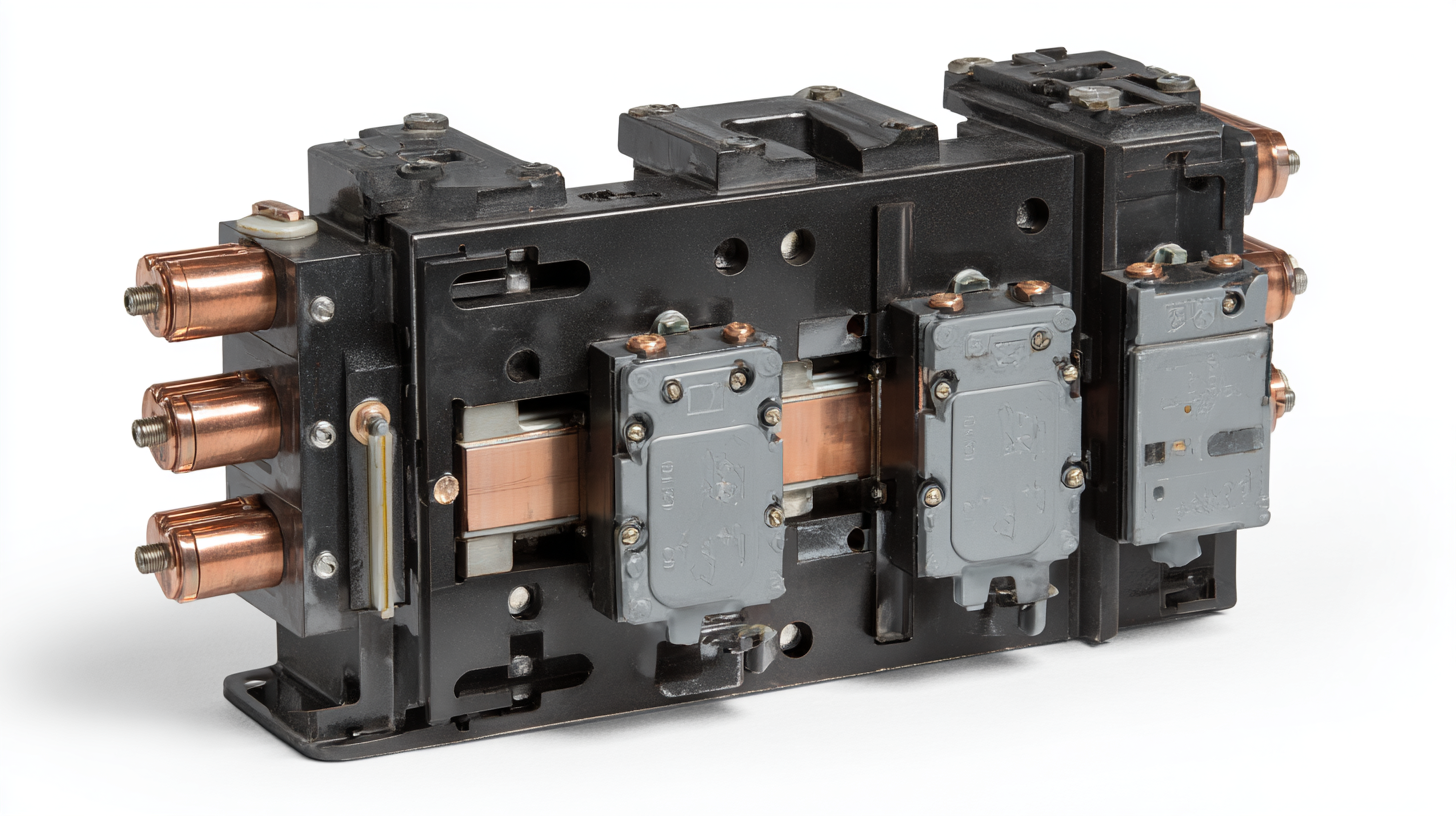

Innovative Materials for Improved Durability and Performance in Vacuum Circuit Breakers

The evolution of vacuum circuit breakers (VCBs) is greatly influenced by the innovative materials used in their construction, significantly enhancing their durability and performance. Advancements in composite materials and ceramics have emerged as key players in this transformation, allowing for improved insulation properties and resistance to environmental stresses. These materials not only extend the lifespan of VCBs but also ensure consistent operation under varying conditions, which is vital for maintaining safety and efficiency in electrical systems.

In addition to traditional materials, the incorporation of advanced alloys and polymers has led to remarkable improvements in the contact surfaces of VCBs. These innovations reduce wear and tear, enabling the breakers to withstand high-frequency operations without compromising performance. With enhanced thermal and mechanical properties, these new materials contribute to the overall reliability of vacuum circuit breakers, making them a preferred choice for modern electrical installations seeking effective solutions to manage safety risks while optimizing energy efficiency.

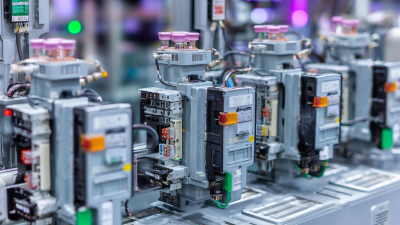

Advanced Monitoring Systems for Real-Time Fault Detection and Analysis

In recent years, the vacuum circuit breaker (VCB) industry has witnessed significant innovations aimed at enhancing safety and efficiency. One of the most impactful advancements is the development of advanced monitoring systems designed for real-time fault detection and analysis. These systems utilize sophisticated algorithms to continuously evaluate operational parameters, allowing for immediate identification of anomalies that could lead to failures. This proactive approach not only minimizes downtime but also extends the lifespan of electrical equipment.

Tips for effective implementation of monitoring systems include ensuring all components are compatible and regularly updated. Additionally, investing in training for personnel can greatly enhance the system's effectiveness. Users should periodically review system performance and calibration to maintain optimal operation.

Furthermore, as safety is a top priority, the integration of remote monitoring allows operators to oversee the circuit breakers from a safe distance. This capability proves invaluable in hazardous environments where access can be limited. Being able to receive alerts and perform diagnostics without being on-site drastically improves response times to potential issues.

2025 Top 5 Vacuum Circuit Breaker Innovations for Enhanced Safety and Efficiency

This chart displays the impact ratings of the top five innovations in vacuum circuit breakers projected for 2025. Each innovation is assessed on a scale from 1 to 10 based on its contribution to safety and efficiency in electrical systems.

Enhanced Insulation Technologies for Increased Safety in High-Voltage Applications

The advancements in insulation technologies are crucial for ensuring safety in high-voltage applications. As the demand for efficient energy solutions grows, innovative materials are being developed to enhance the safety of electrical grids. For instance, the ongoing research into eco-friendly gas alternatives to traditional insulating gases is paving the way for more sustainable electrical networks. These innovations not only promise a reduction in environmental impact but also aim to improve the reliability of high-voltage systems.

Quality insulation is vital, especially with the rising concerns regarding the operational safety of electric vehicles and other high-voltage applications. Recent developments in coatings specifically tailored for extreme heat protection demonstrate the potential for better electrical insulation in these systems. Additionally, the introduction of insulation monitoring devices enhances safety measures in electrical infrastructure, allowing for real-time monitoring and timely responses to potential hazards.

**Tips:** When considering insulation materials, prioritize those that exhibit both high dielectric strength and resistance to environmental stressors. Regularly assessing the effectiveness of insulation in high-voltage applications can prevent safety incidents and ensure optimal performance. Staying informed about innovative technologies can lead to smarter choices in component selection for future projects.

Smart Automation Features for Streamlined Operation and Maintenance

The integration of smart automation features in vacuum circuit breakers is transforming the landscape of electrical safety and efficiency. These advanced systems are designed to enhance operational reliability while minimizing human error. Real-time monitoring capabilities enable operators to evaluate the performance of the circuit breakers continuously, allowing for timely interventions whenever abnormal conditions arise. This proactive approach not only ensures the safety of electrical systems but also prolongs the lifespan of the equipment.

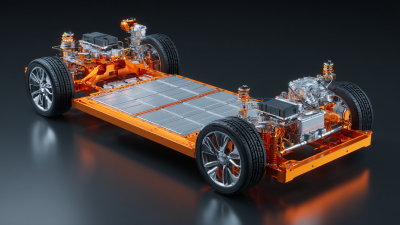

Eco-Friendly Designs and Energy Efficiency Trends in Circuit Breaker Innovations

As the demand for sustainable energy solutions grows, vacuum circuit breakers (VCBs) have entered a new era of eco-friendly designs and energy efficiency trends. In 2025, innovations in VCB technology will focus on reducing environmental impact while enhancing performance. These advancements include the use of recyclable materials in manufacturing and the implementation of energy-saving features that minimize power losses during operation.

To maximize energy efficiency, consider organizing regular maintenance schedules for your circuit breakers. This can help identify any inefficiencies and ensure optimal function. Additionally, investing in smart VCBs that integrate IoT technology can provide real-time monitoring of energy consumption, allowing for proactive management of resources.

Moreover, manufacturers are looking into creating compact, lightweight designs that not only save space but also reduce the carbon footprint associated with transportation and installation. These innovations reflect a broader commitment to sustainability within the power sector, promoting a greener approach to energy management. Adopting such technologies in your facilities can lead to significant cost savings driven by enhanced efficiency and reduced waste.

2025 Top 5 Vacuum Circuit Breaker Innovations for Enhanced Safety and Efficiency - Eco-Friendly Designs and Energy Efficiency Trends in Circuit Breaker Innovations

| Innovation | Safety Features | Energy Efficiency (%) | Eco-Friendly Material | Installed Cost ($) |

|---|---|---|---|---|

| Smart Protection System | Overcurrent & Short-Circuit Detection | 95 | Recyclable Plastics | 5000 |

| Automatic Isolation Function | Automatic Shutdown on Fault | 90 | Biodegradable Insulation | 5500 |

| Remote Monitoring Capabilities | Real-Time Fault Monitoring | 92 | Sustainable Metals | 6000 |

| Integrated Communication Systems | Emergency Alerts & Notifications | 93 | Recycled Metal Components | 5800 |

| Optimized Arc Extinction Technology | Low Arc Energy Emissions | 89 | Eco-Friendly Coatings | 5300 |

Related Posts

-

Exploring the Future of Energy: The Role of Vacuum Circuit Breakers in Smart Grids

-

5 Practical Tips for Maximizing Energy Storage Battery Efficiency

-

Exploring the Future of Energy Storage with the Best Lithium Polymer Battery Technology

-

Mastering the Essentials of Lithium Ion Car Battery Maintenance for Longevity

-

Understanding the Future of Energy Storage Battery Technology Innovations and Applications

-

How to Ensure Import Export Certification for the Best Vacuum Circuit Breaker